CNC Drill Holder

Using the CNC Router in the Fabrication Lab

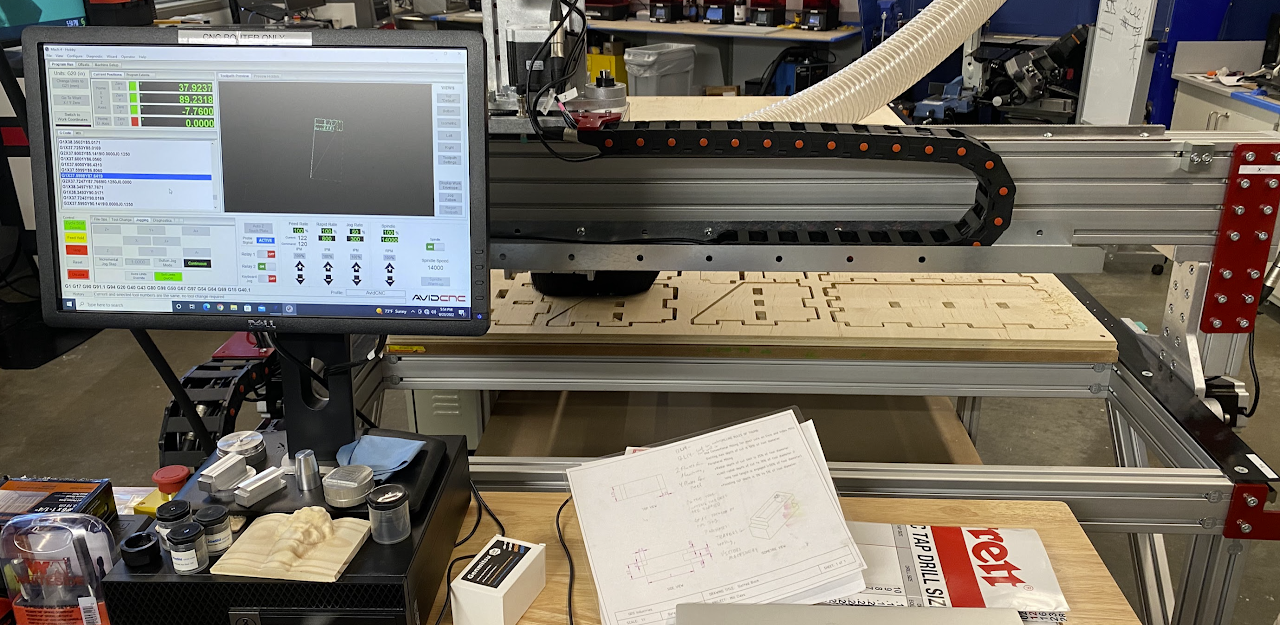

MIX Makerspace Associate Nathan recently completed a project for the new Woodshop space using the CNC router in the MIX Fabrication lab. Nathan detailed his work and experiments in learning how to use the CNC to make the necessary parts in his own blog, copied below.

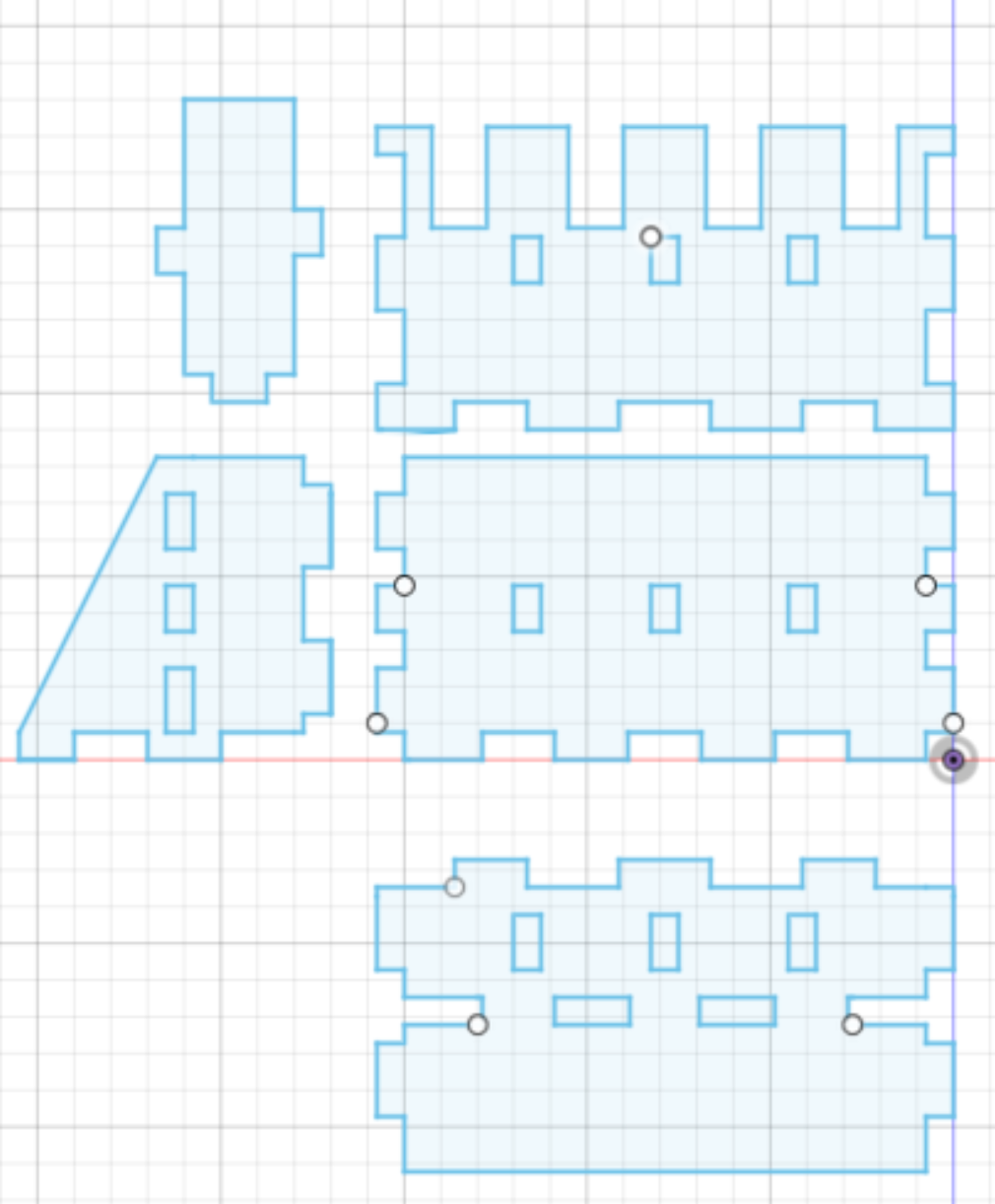

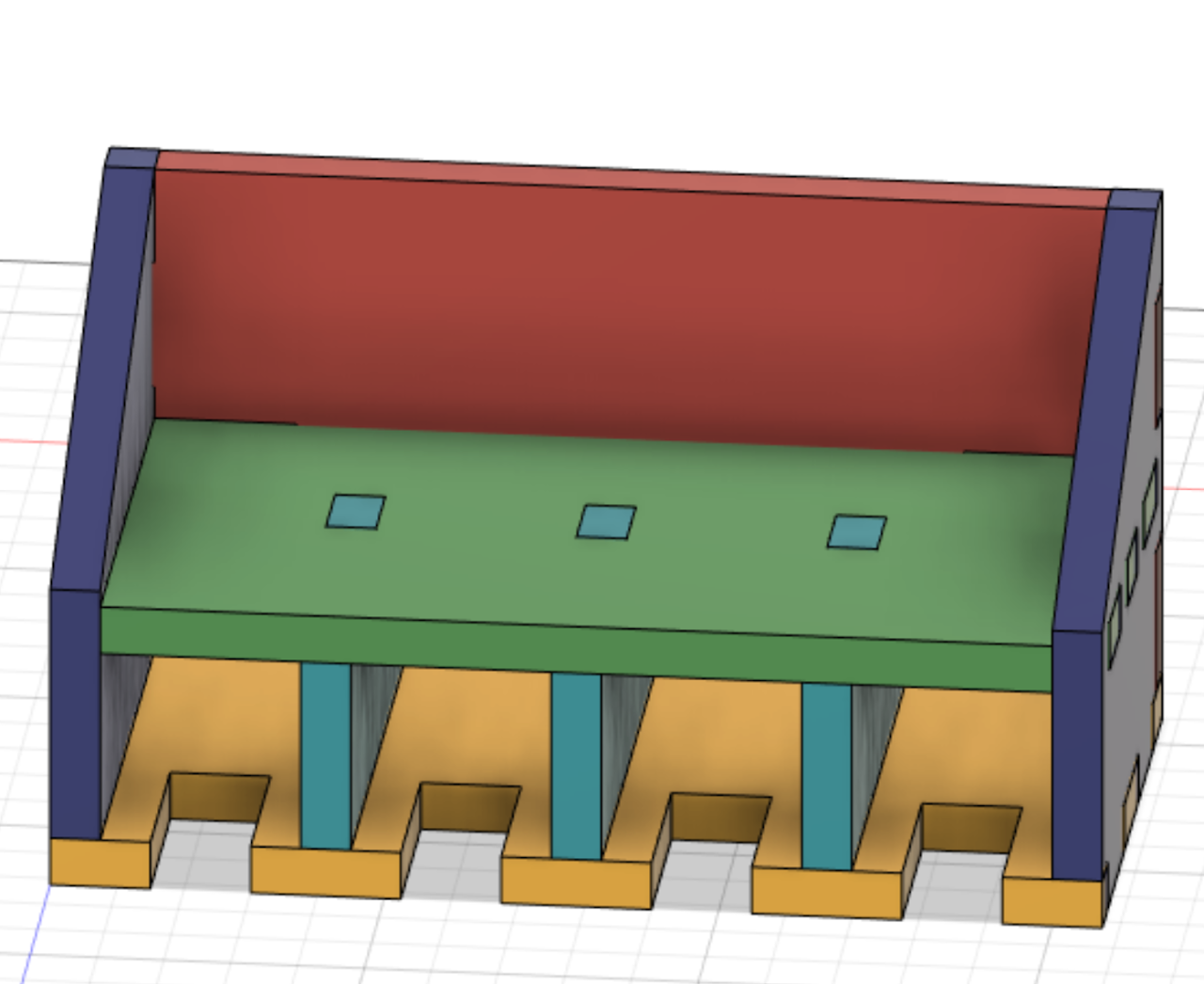

“At the Mason Innovation Exchange(MIX), which is where I work at George Mason University, we got a bunch of new equipment to build up a small woodworking shop. One of the main things we got were new cordless power tools. My boss tasked me with making a holder for the drills that would keep them accessible, visible, and easy to grab since we had been keeping them in a toolbox. I designed a holder in Fusion360 made up of 8 pieces that could be cut out with the CNC router. Once everything was made in CAD, I exported the 2D sketches of the models as DXF files to the CNC router.

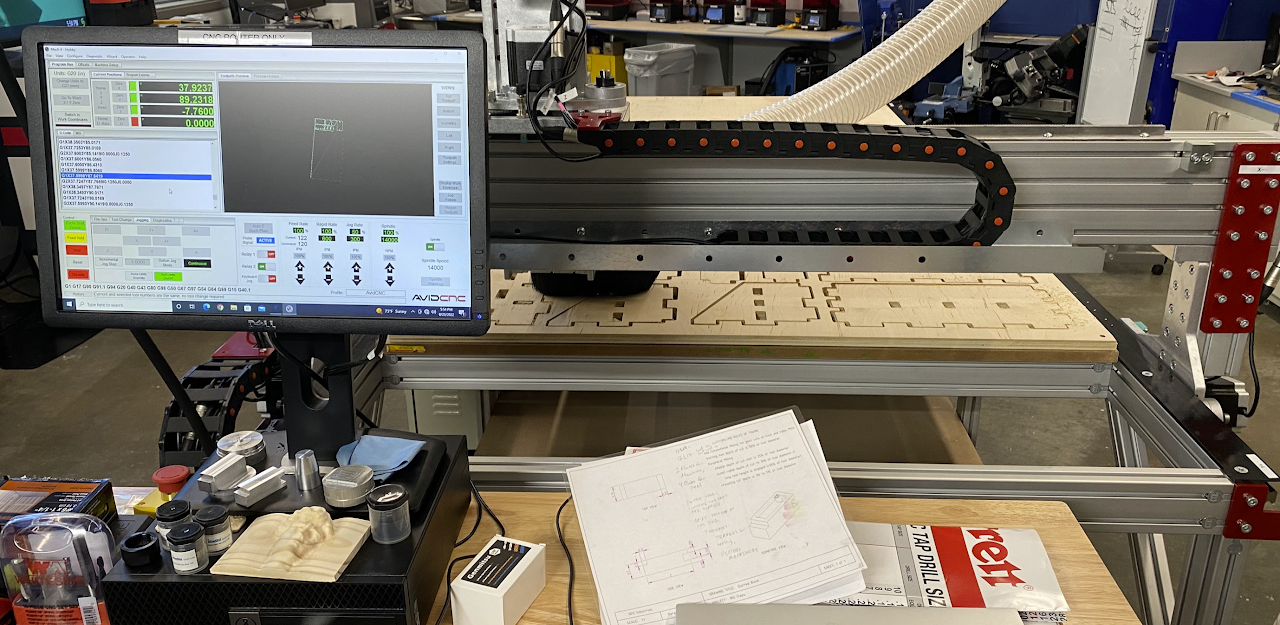

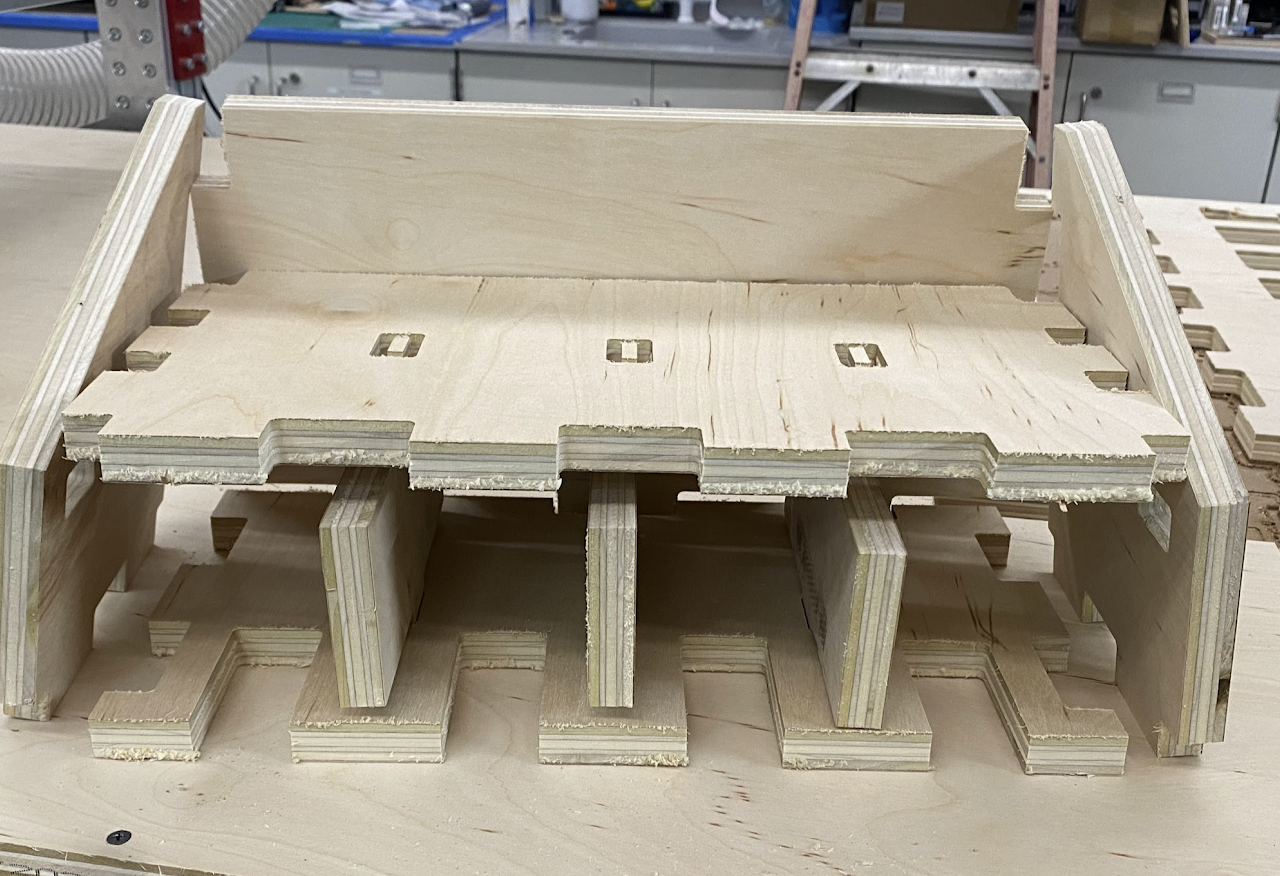

Once everything was ready to be cut the DXF files were uploaded onto the CAM software for the CNC and a piece of 3/4in plywood was secured to the CNC router. After doing all the necessary preparations for cutting the job was run and the pieces were cut out. The assembly required a little bit of sanding, some wood glue, and trim nails for good measure and then the finished product was hung on the wall.”